Because of my limited qualifications all boats that were built by my company to my own design originated from a half block model that I made. The model was built up from a series of softwood planks each being 3/4 inch thick. The model was always made to a scale of 3/4 inch to the foot; a very simple equation to use when converting to the true measurements in the table for use on the loft floor. From this model tables of offsets and dimensions could be prepared and quantities of materials could also be calculated.

Because of my limited qualifications all boats that were built by my company to my own design originated from a half block model that I made. The model was built up from a series of softwood planks each being 3/4 inch thick. The model was always made to a scale of 3/4 inch to the foot; a very simple equation to use when converting to the true measurements in the table for use on the loft floor. From this model tables of offsets and dimensions could be prepared and quantities of materials could also be calculated.

Our loft floor was a pretty simple arrangement; a series of pineboard sheets large enough to accommodate the full size of the new vessel was all that was required.

After building the model and laying out the floor this is the procedure used to build the boat:

After building the model and laying out the floor this is the procedure used to build the boat:

Divide the model length into a series that represents the number of fixed frames that the boat was required to have, usually at 4 foot centres.

On the pineboard floor draw a series of lines horizontally at a regular distance of 12 inches (1 foot) apart to represent the waterline.

Draw a further series of lines vertically; these lines are referred to as buttock lines, again at a distance of 12 inches apart. One of these is then selected as the centre line of the boat and the contents from the tables that were previously prepared can now be transferred to the full size grid of waterline and buttocks.

Again from the model prepare full sized templates of the stem profile and transom deadwood to be used to make the full sized components of the boat. Once this task is completed you are now ready to start production on the fixed frames.

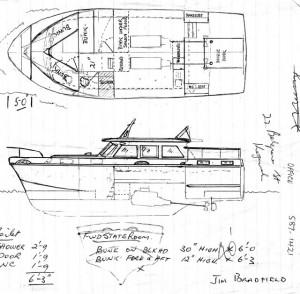

The profile of the model is now transferred to paper on the drawing board and the outline of the superstructure is drawn up on top of the hull; this is where you get to create your impression of the finished product. The balance of superstructure to hull is most important in creating a good looking boat.

The profile of the model is now transferred to paper on the drawing board and the outline of the superstructure is drawn up on top of the hull; this is where you get to create your impression of the finished product. The balance of superstructure to hull is most important in creating a good looking boat.

When the frames and all component parts have been completed the assembly can proceed. The keel stem and sternpost are all put together and set up in the floating position of the finished job. The frames are set up in their positions; everything being level and plumb and ready for a component known as ribbands to be set into the frames longitudinally.

When the frames and all component parts have been completed the assembly can proceed. The keel stem and sternpost are all put together and set up in the floating position of the finished job. The frames are set up in their positions; everything being level and plumb and ready for a component known as ribbands to be set into the frames longitudinally.

Ribbands are used to help the hull keep its shape and as a fixing point as the hull is progressively planked. Prior to the upper ribbands being fitted what is known as floor timbers are fitted. These are transverse hardwood pieces usually 12 inches x 2 inches set upon the ribbands in the bottom of the hull and through bolted through the keel structure usually 2 between each frame. They carry 4 longitudinal full length engine beds and combined they form the real strength of the boat. As most of my boats had twin screws, inside blocks known as shaft logs are positioned and pilot bored to accommodate the future inside bearing of the tailshafts. Chines and stringers are set into the frames also and after this the whole structure is ready for planking.

Ribbands are used to help the hull keep its shape and as a fixing point as the hull is progressively planked. Prior to the upper ribbands being fitted what is known as floor timbers are fitted. These are transverse hardwood pieces usually 12 inches x 2 inches set upon the ribbands in the bottom of the hull and through bolted through the keel structure usually 2 between each frame. They carry 4 longitudinal full length engine beds and combined they form the real strength of the boat. As most of my boats had twin screws, inside blocks known as shaft logs are positioned and pilot bored to accommodate the future inside bearing of the tailshafts. Chines and stringers are set into the frames also and after this the whole structure is ready for planking.

Planking may now proceed and if I was building a hard chine game boat, the procedure would be 2 diagonal layers or skins and a final layer fore and aft all laid up in epoxy glue and fastened at chine, ribbands and gunnel.

The next stage is to set out the deck frame. This determines the length of fore deck, trunk cabin, main saloon and cockpit. On completion of this and after fairing, the deck is laid and the outside gunnel is attached.

Basically, timber work on the hull is now finished and at this stage of construction you feel pretty good but from experience you are only about 25 % into the project. From here the fitting out becomes basic joinery woodwork, plumbing and electricals; the ability of the finisher determining the final outcome.

Basically, timber work on the hull is now finished and at this stage of construction you feel pretty good but from experience you are only about 25 % into the project. From here the fitting out becomes basic joinery woodwork, plumbing and electricals; the ability of the finisher determining the final outcome.

When most people look at a boat it is the superstructure and fit out that takes their eye but these are mostly cosmetic. In a heavy sea the structure and strength of the hull is the most important feature.

As a tradesman and a person that enjoyed my job and built boats pretty much of all my working life I approached my occupation as a person responsible for the lives of others and at all times did my best to ensure that the quality of the work and of all components that we used were the best available at that time.

I can attest to the strength of Peter’s hull design. I previously owned one of Peter’s 36ft flybridge cruisers (Kalizma) and steamed her from Nelson Bay to Paynesville. We got caught in a southerly buster near Broken Bay in November 2012 and the seas were somewhat challenging with whitewater regularly coming over the bow. Suffice to say, she was rock solid and rode the swell beautifully. We covered nerly 500nm on that journey in an average of 2-3m swells and she never missed a beat.

Did the Abacore 32ft boats have a single engine and if so what engine did they have?

Peter replied:

Sailfish a definite twin screw Perkins she was 38ft — Albacoral 1– I think a single then Claude’s second boat a twin. The Police 32 footers were all twin screw—- originally petrol Mercruisers and then later on to Caterpillar diesels after the Baldwin exploded.

I notice Albacora is listed as a 32Ft single but then reading further it sounds like Peter built a second boat for Claude Archer are there any specs for the second boat? was it also called Albacora and when was it built

Peter has clarified things a little.

The Albacora on the website is the first boat built by Peter for Claude Archer. It was a 32 footer powered by a single Perkins 60354.

Peter subsequently built a 40 footer for Claude powered by twin Perkins. It was probably also called Albacora but we’re not 100% certain. Unfortunately there are currently no photos or records of the 40 footer. If anyone has a connection or knows of this boat please post a message.

The original Albacora 32 is powered by a perkins 6354 ht single which was the first boat Peter built for Claude launched 1970 and currently moored on the George river Sydney.

The 40 ft Albacora is currently for sale on the internet but is in quite poor condition.

Yes I fished both boats and both were called Albacora by the owner Claude Archer.

That’s correct albarcora is a single Perkins 6354 ht launched 1970 as I am the current owner

Hi guys,

I have a 1973 bracken with a ford lehman Diesel engine , it is a 32 footer

And was named Utopia so I am told. Does anybody know anything about

This vessel and is there a easy engine swap for it as it slow and noisey

G’day Peter, any information on sailfish around? she’s a 1970 38′ flybridge twin screw. Cheers

Sailfish was built for Eric Howarth —–originally she was strip planked and later returned to our shed and the topsides were fitted with another skin of planking which was glued with epoxy glue diagonally to the original—- this allowed us to be able to get a better finish to the topsides surface for Dynal sheathing ( glassing ) all of my boats of multi skins were sheathed with dynal cloth and epoxy resin in the shed as part of the original build and the job was done by my employees

There was one exception to this procedure Stan Edwards boat was sheathed by others and they used polester resin instead of epoxy and in a short time the sheathing delaminated and had to be replaced by the original people with epoxy

All glues used by my team were epoxies and the supplier was Epiglass a N.Z. company who were the leaders in the field at the time the y were in business at Botany if my memory is correct

Hope this helps —-I actually fished on occasions on Sailfish we were at Port Stevens for the annual game fish tourney one year and hooked up a marlin at about 3.30 p.m. and were still on after dark miles to sea no idea where we were got busted off and we headed west looking for home motored all night and as dawn broke found ourselves off Nobbys at Newcastle a very long way back to the Port ( the skipper was a bit embarrassed )

BYE NOW pete

Yes I was on the 32ft cruiser on her very first game fishing trip to The Peak, and caught a 110lbyellowfin with Claude and my father, she has amazing stability and nice wide decks to walk around the boat, the 40 foot Alabacora was purchased recently by a retired gent who contacted me and I will follow its restoration. it is sadly neglected by a previous owner her informed me. It is moored up river of the Hawkesbury road bridges somewhere!

Vincent I would dearly love to see your 32ft Albacora sometime with your permission, I spent many weekends on her!

Contact me via my email if possible

I also have a photo Claude gave my Dad ,who was his best mate.

It was a Friday drinks party at the launching or keel laying not sure whether it was the 32 or 40, would like to post the photo sometime if possible, Peter and staff are in the pic!

cheers to all

Oops that photo is already under ALBACORA sorry!

Hi Graham I would love to see any photos off Albacora my email address is vince.finocchiaro@acegutters.com.au the original owner off peterlyn was part owner off the company I work i still see his grandsons.

Does anyone know of “ Nomad”, at 32 ft., twin Cummins, said to be Halvorsen design but Bracken built, launched at Doolans Bay in 1976 by a distinguished RMYC lady?

Vessel now is on the Gold Coast.

Appearance is like Falcon in the photo.

Does anyone know of “ Nomad”, at 32 ft., twin Cummins, said to be Halvorsen design but Bracken built, launched at

Dolans Bay in 1976 by a distinguished RMYC lady? Perhaps her then new owners were Messrs. Cooper and Barton

Vessel now is on the Gold Coast.

Appearance is like Falcon in the photo.

TO LEO WHITE Yes Le I did build that boat for Harry and Bruce (THE BLACK PRINCE ) THIS WAS A JOINT VENTURE FOR THEM—Ihad previously built for Harry a 26 footer all launched at Dolans Bay Pot Hacking regards PETER B

Hi Peter B,

Nomad is back in Sydney and for sale. Can you advise a reputable wooden boat person to undertake an inspection for me, a newbie?

Answered privately

Hello

I am interested in “Maluka” presently for sale in Rosslyn Bay.

Does anybody know if the construction is identical to that of “Helen B” which has some great pictures on the website?

Because of some pontoon mooring limitations I am also interested in the accurate length of Maluka from Bow Stem to Transom. Advertised as a “42”, it makes quite a difference to us if she is in fact 39 feet or less.(excl. duckboard and bowsprit)

Also, she is advertised as a 1971 build, but I assume she is 1963 as she is listed on the website.

Any information on this pretty boat would be appreciated.

Hello again

I am still trying to gather information on the vessel I mention above. I realised when I looked at a transom picture that it is named “Maluka 111”. This link opens a great profile picture.

https://www.boatsonline.com.au/boats-for-sale/used/power-boats/bracken-timber-flybridge-cruiser/252950

As well as length bow stem to transom, I am also trying to determine whether the vessel hull was dynel or fibreglass sheathed ex Peter Bracken’s factory.

I am sorry but I do not understand the protocols of this site – I notice there are email threads under almost all the tabs.

I would be grateful for any help. Thanks.